Today we would like to introduce the reason of why need to Reverse Engineering Old Printed Circuit Board, with the continuous development of society, the level of science and technology has also been continuously improved. At present, the cycle of updating electronic products in the society is very short.

This will cause a product to be discontinued about two to three years after a product being launched (because the upgraded version of the product has already flowed to the market, and the market share of old products has gradually declined, continue to produce old products, there is no advantage in terms of comprehensive benefits).

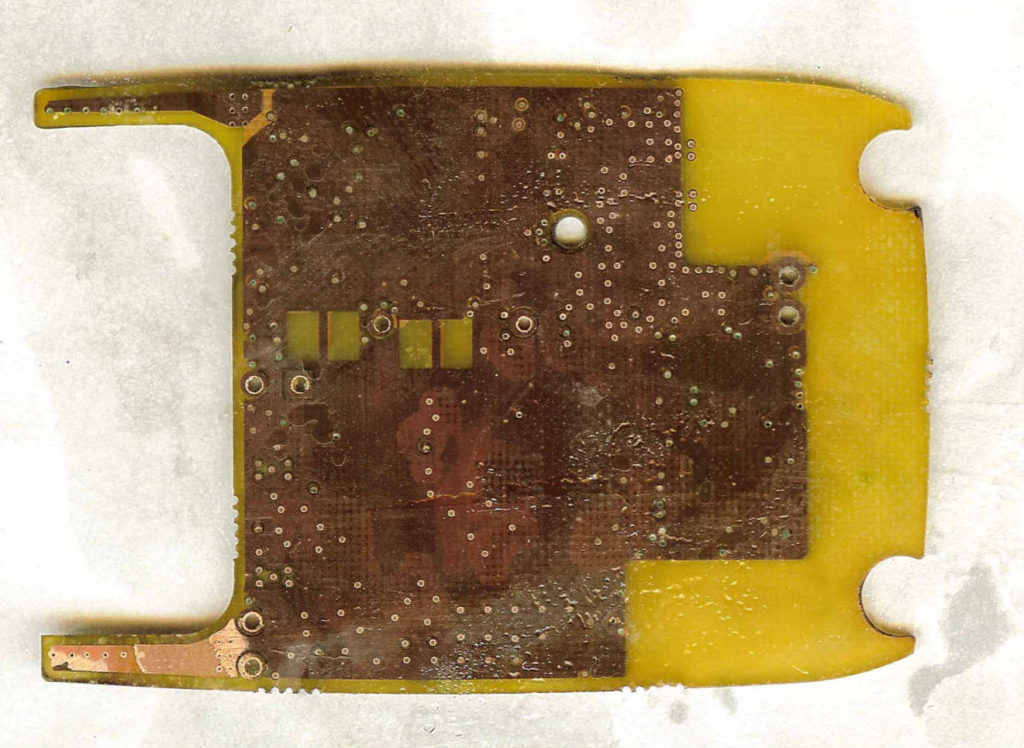

This will be a disaster for the customers who bought this product in the early stage. The reason is that after the printed circuit board of the production equipment has worked for a certain period of time, the probability of failure will increase. If there is a problem with the control board and the manufacturer has stopped production, So what can customers do at this time?

The previous approach was:

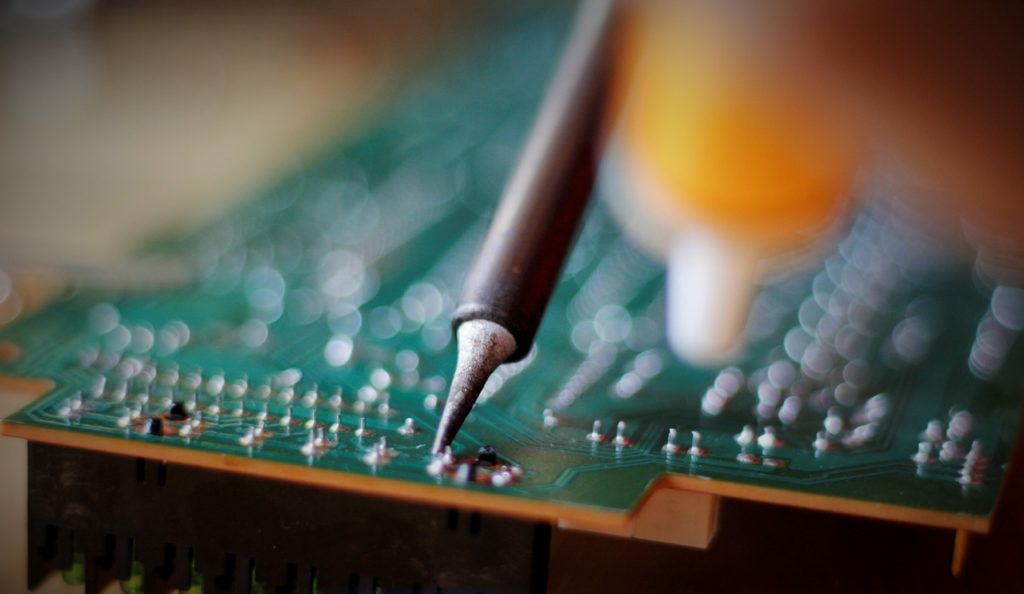

① Find manufacturer technical personnel or equipment maintenance personnel in the enterprise to analyze the fault problem and seek solutions, and now large-scale applications such as integrated circuits and chips in the control board, therefore, it is rare to be able to rework the control board directly and succeed;

② Purchase new equipment to replace the production equipment that has failed and cannot continue to work, this method is normally will cost great amount of money and lead time will be expanded to an undurable extend;

Summarize all the factors above, we have to consider the necessity of printed circuit board reverse engineering;