Rework Siemens MRI Controller PCB Board by Circuitry Maintenance Tester is an effective and effecient way, It is a new type of motherboard maintenance tool. Its main feature is that it can detect the function, state and external characteristics of components on the circuit board, i.e., the curve, and confirm whether it fails. Because “curve analysis” is not limited by the shape of the chip, and can be used to test various discrete components, it is of great significance to locate the fault point.

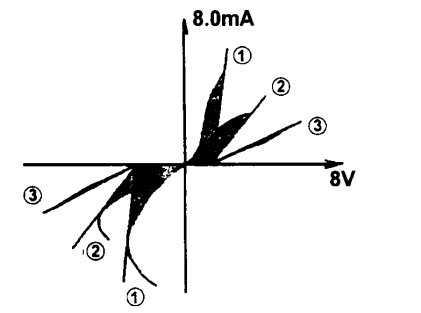

When performing “curve analysis”, the tester applies a scanning voltage of a fixed frequency to the node under test, and detects the corresponding current, so as to obtain the dynamic impedance curve of the node. When the device connected to this node fails, it will appear on the curve, such as capacitor breakdown, resistance change, short circuit, open circuit, etc. Here is an example of repairing a MRI motherboard for illustration.

Method for detecting gradient compensation board of nuclear magnetic resonance machinery:

The board is composed of three parts. Each part has the same structure. By comparing the node curves of the same part directly, When there is a significant difference between one and the other two, it is judged as a failure; combined with the analysis of the PCB board circuitry diagram extracted by PCB reverse engineering, the cause of the fault can be found out.