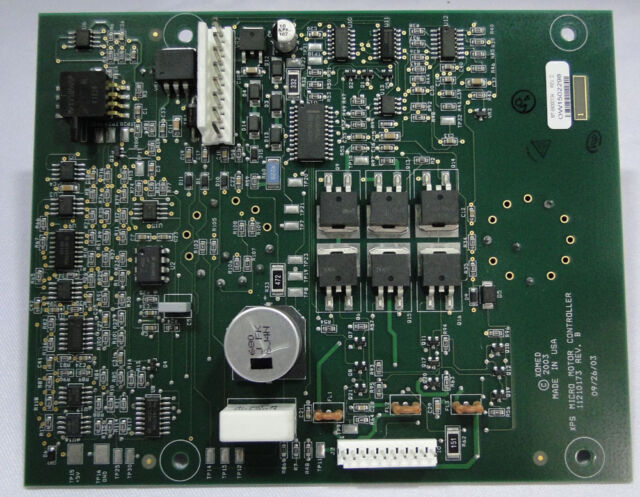

Hereby we would like to share an example about Rework Medtronic Ultrasound Machine Motor Control Board:

After turning on, the normal interface of Motor Controller Board has been found not able entered. The 60 code is displayed on the total number of controller board display tube. according to the description of original manufacturing there is no such error code. During the test, it was found that as long as any key on the control board is pressed, the “blade Height ” value will display.

According to original manufacturer description is that the machine has entered the “height adjustment mode”, but the operational manual only explains how to enter this mode (press and hold the ELNA key to turn on until it enters the adjustment mode), but does not explain how to exit the mode; as a result of that, the Medtronic Ultrasound Motor Controller can’t quit using multiple methods provided by the manufacturer, furthermore we are lacking of schematic diagram or layout drawing of the circuit board which has brought great troubles for recovering this circuit board. It is possible to extract schematic from Motor Controller Board by reverse engineering but the price is too big to afford;

The Rework Medtronic Ultrasound Motor Controller Board job was at an impasse and the previous failures have found the cause and solved them one by one. It would be a pity to scrap it. comprehensive inspection has to been conducted for analysis of the ultrasound machine’s failure. it has been guessed that the “adjustment mode” was turned on and the dean key was short-circuited.

However, removing this button is normal, and the meter still enters the “adjustment mode” when the power is turned on. With the previous experience, we continued to test and analyze. Is it the same as before because the SV power is not connected to the push button switch, so that the claen key signal is always low?

However, it was found that the positive S V voltage of the push button switch was normal after measurement. Finally, It has been found out that the signal of the lCENA key was also transferred to the logic control CI in the motor controller board through TTL and MOS through the NAND gate, and this signal line passed under the extension button of the cutter head. After measuring it with a multimeter, it turned out to be the case. After welding with thin copper wire, the machine can enter the normal interface. Since this button is often pressed, the above screen and the skin has been damaged. It is possible that the grease and sweat from the fingers have eroded the printing line. To prevent this kind of trouble from happening again, a layer of silica gel has been painted to serve the purpose of sealing. Similar failures have never occurred since then. The Medtronic Ultrasound machine is currently used normally.