Rework Integrated Chip on the Broken GENERAL Computer Tomography needs to desolder and replace the chip prone to failure, it can be replaced with a chip socket, which is convenient for future chip replacement or elimination test of unstable chip failure.

Some chips are inexplicably damaged, mostly due to electrostatic discharge. The general chip antistatic voltage value is 1000V ~ 2000V.

The TIL chip is about 1000V, the NMOS chip is about 500V, and the EPROM chip is only about 200V. The static voltage of the human body is generally tens of thousands of volts. Therefore, in the circuit board maintenance operation, you should pay attention to the use of anti-static bracelets to prevent accidental chip damage.

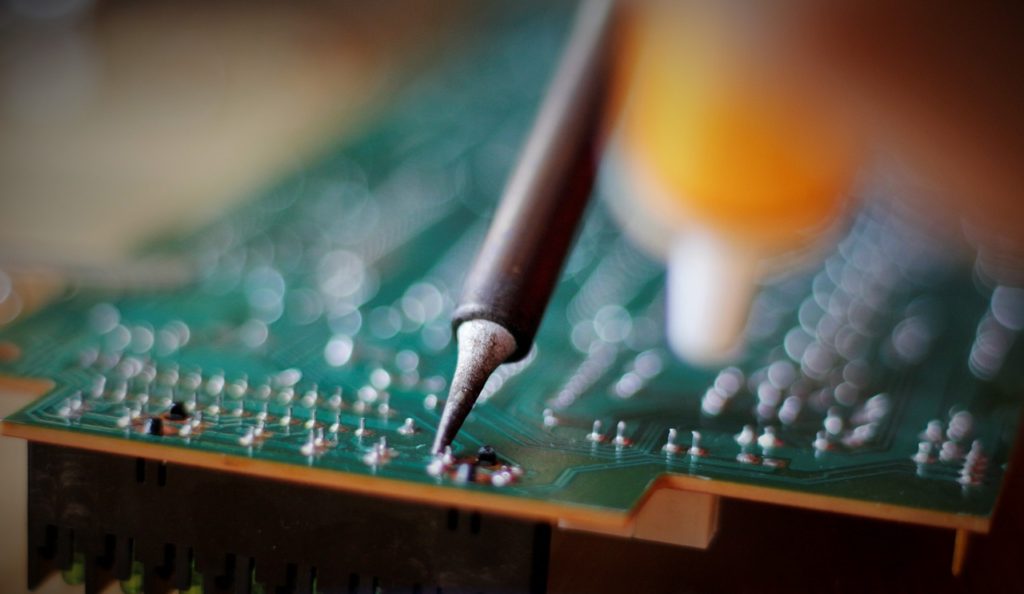

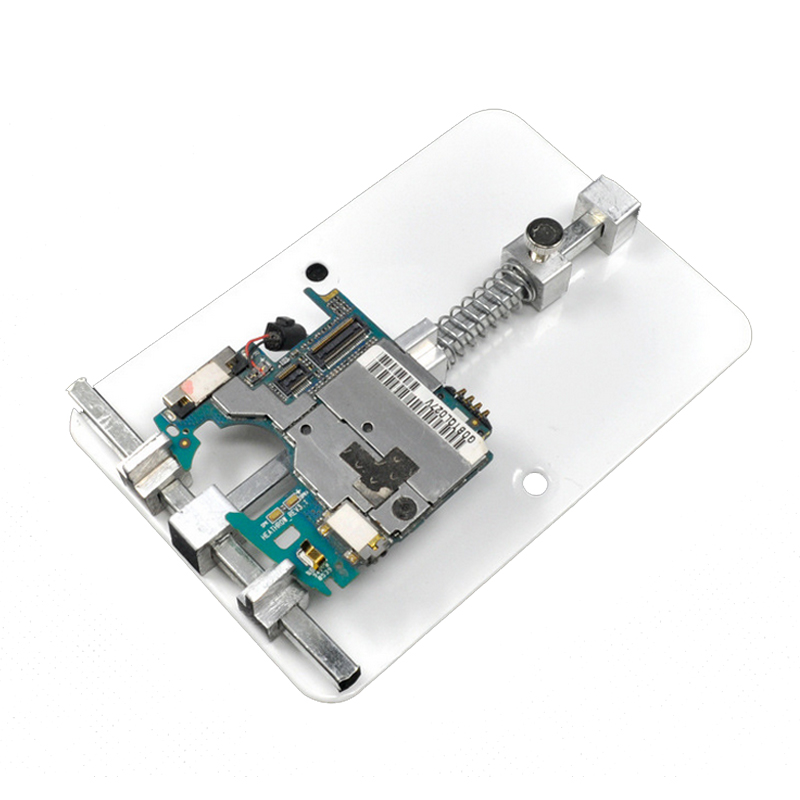

The soldering of the chip is also a problem that can’t be ignored. Otherwise, the faulty chip is found, and it is just that it can’t be replaced. The small wave soldering machine and the tin removal table can easily pick up and solder ordinary IC chips, replace the fixture to remove and solder the surface-mounted gate array chips, etc. It is a higher-level soldering tin removal equipment, but the price is more expensive.

The air chestnut type tin suction device is suitable for the removal of various chips or unit devices by replacing various tin suction heads, and is an ideal maintenance tool. The use of low-grade tin absorbers is very easy to cause damage to the soldering holes of the circuit board, so that the previous work is abandoned, you should pay attention.

In chip-level maintenance, be careful not to reduce the quality level of the chips and devices used. It is best to perform aging treatment and cycle function test on the new device before putting it on the machine to ensure the quality of the repaired circuit board.