Reverse Engineering Electronic PCB Card ESD Design provide designer an effective way to improve the ESD performance of printed circuit board, because sometimes the original PCB board esd design is not as good as expectation;

Reverse Engineering Electronic PCB Card ESD Design provide designer an effective way to improve the ESD performance of printed circuit board, because sometimes the original PCB board esd design is not as good as expectation

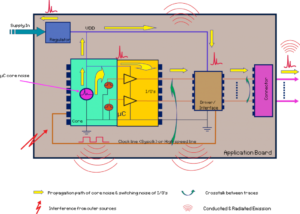

If the circuit board will not be placed in a metal chassis or shielding device, solder mask should not be applied to the top and bottom chassis ground of the circuit board, so that they can be used as discharge electrodes for ESD arcs.

Set up a ring ground around the circuit in the following way:

(1) In addition to the edge connector and chassis ground, place a ring-shaped ground path around the entire periphery.

(2) Make sure that the width of all layers is greater than 2.5mm.

(3) Connect the ring with a via every 13mm.

(4) Connect the ring ground and the common ground of the multilayer circuit board reverse engineering together.

(5) For a anti-esd double-sided pcb board reverse engineering design installed in a metal chassis or shielding device, the ring ground and the circuit ground should be connected together. The unshielded double-sided circuit should connect the ring ground to the chassis ground.

The ring ground can’t be coated with solder resist, so that the ring ground can serve as a discharge rod for ESD.

Place at least one at a position on the ring ground (all layers) the 0.5mm wide gap can avoid the formation of a large loop. The distance between the signal wiring and the ring ground shouldn’t be less than 0.5mm. In the area that can be directly hit by ESD, a ground wire should be placed near each signal line.