Reverse Engineering Circuit Board Material Analysis

Reverse Engineering Circuit Board Material Analysis Objective

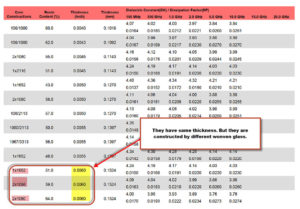

The material analysis, including chemical and metallurgical analysis, should be performed to determine the composition, surface treatments, finishes, hardness, and heat treatments pertinent to each piece-part/component. since circuit board can be made by various material from Fiber resin with glass cloth, the fiber resin can be classfied from rank 1 to rank 4, as well as inflamable level, dielectrical parameter, coefficient parameter, hardness, etc.

Different circuit board raw material will be applied on various environment, for example, the high TG point material will normally used on the harsh and complicate scenario which need the electronic device to surface high temperature, high moisture, high salty level. regarding the other signal transmission scenario such as the antenna, signal relay basement, and signal amplifier, mobile signal station, teflon or ceramic material will be chosen for these kinds of scenarios, so before we reverse engineering circuit board received from customers, it is necessary to know its working environment and condition;

Reverse Engineering Circuit Board Material Analysis

Sample size

Spectrographic samples should be submitted for composition analysis and identification of elements. The suggested sample size is: 1” X 1” X 1,” as smaller-sized samples are less cost efficient and may prohibit the use of instrumental analysis. The material analysis for plastic parts usually requires as much as one month additional time. Where possible, samples should be submitted in their entirety for metallurgical analysis. for some of the plastic or metal enclosure, if the internal structure is too small or complicate to be measured, engineer need to use the 3D scanning technique to get the 3D drawing of it for subsequent reverse engineering. Improper cutting of the sample could affect the hardness readings or the interpretation of the heat treating process.