Reverse Engineering Circuit Board has no software; therefore, it can only be measured and drawn using calliper edge, which it’s quite sluggish, and its precision is also bad. However, it is extremely easy to copy the PCB board with the program. Generally, it is more convenient to utilize the PC board cloning software of delta firm. You can scan or take a picture of the PCB board first and then load the picture into the software according to the gourd sketching ladle. But it’s more difficult to turn the PCB layout diagram and Gerber File into the schematic diagram because it demands experience and understanding; else, it can’t be done effectively.

Reverse Engineering Circuit Board Introduction

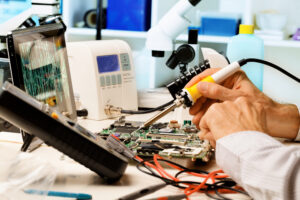

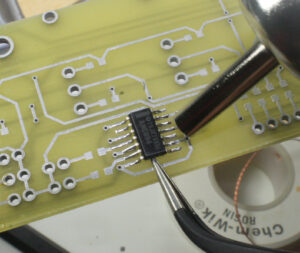

It is more challenging to re-manufacture the multi-layer electronic board because the inner layer cannot be seen; thus, we can only harm the sample. Generally, we cope on the top and bottom first and then keep the bottom and the top down in front of the photo. Besides, an accurate approach is to de-soldering all components, register all components parameters and number one by one of the components and silkscreen layer corresponding to keep the original information, or scan again to bare PCB photography, get images or scan in software. After the upper and lower layers are done, the finished layer can be polished with sandpaper to gradually expose the inner layer, copy one layer and then grind the next layer until all is completed.

The printed circuit board reverse engineering technology is used to reversely analyze the PCB, as well as the original product PCB design file, bill of materials (BOM) file, schematic diagram, and other production documents

The printed circuit board reverse engineering technology is used to reversely analyze the PCB, as well as the original product PCB design file, bill of materials (BOM) file, schematic diagram, and other production documents, such as PCB Gerber file and PCB silkscreen, under the premise that there are already physical objects and circuit boards of electronic products. Meanwhile, using MCU cracking technology to read embedded binary or Heximal firmware from the PCB board’s programmable microcontroller’s to ensure that cloned printed circuit board functions correctly. Then use all of these engineering and production documents to complete the entire duplication of the original circuit board as a sample, including PCB re-manufacturing, component soldering, flying probe testing, and circuit board debugging.