Repairing Medical Electronic Equipment PCB Board will become easier and more convenient if the daily inspection can be carried out if the reworking has been to executed without printed wiring board schematic diagram;

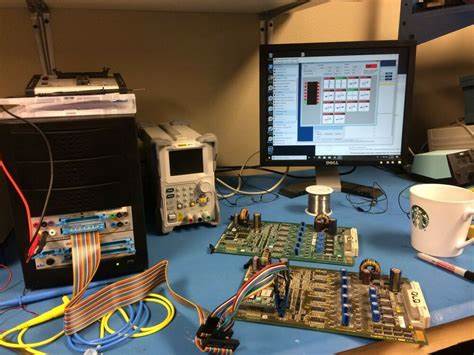

Large-scale medical electronic equipment such as computed tomography and nuclear magnetic resonance is complex in technology. It requires a high-quality and experienced technical team to maintain power supply circuit board and repair MRI mainboard, so that the maximum efficiency of the equipment can be brought into full play.

During the inspection and maintenance, the inaccuracy of the maintenance time, maintenance content, and equipment condition records makes it difficult to distinguish the responsibility from the clinician when there is a medical responsibility problem related to medical equipment.

The application of radio frequency identification technology greatly simplifies the retrieval of regular inspection equipment. The computer system automatically provides the equipment maintenance personnel to be inspected and maintained this month to the equipment maintenance personnel by department or by type.

Equipment maintenance personnel can obtain corresponding and complete information in the shortest time without spending a lot of energy on information retrieval.

And download the equipment information needed for inspection and maintenance to the handheld inspection terminal, Inspection and maintenance according to equipment type or department classification, Save staff time and improve staff efficiency.