Relayout Printed Circuit Board Gerber File must follow some rules strictly in order to ensure the out of standing performance of PCB Board than original one, because the purpose of re-route multilayer pcb board layout design is to improve the original PCB functionality;

Relayout Printed Circuit Board Gerber File must follow some rules strictly in order to ensure the out of standing performance of PCB Board than original one, because the purpose of re-route multilayer pcb board layout design is to improve the original PCB functionality

Because the impact interference generated by the transient current on the line is mainly caused by the inductance of the line, the inductance of the line should be reduced as much as possible. The inductance of the line is proportional to its length and inversely proportional to its width, so a short and wide line is beneficial for suppressing interference.

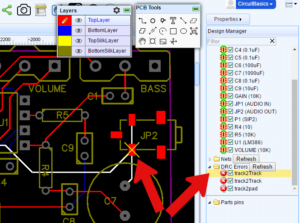

1. The key signal lines should be as thick as possible, and protective ground should be added on both sides. The high-speed pcb board signal lines should be short and straight, and the width of the wires should not be abrupt.

2. Do not form a loop in any signal. If it is inevitable, make the loop area as small as possible.

3. The PCB should use 45 degree fold lines instead of 90-degree fold lines as much as possible, which can reduce the external emission and coupling of high-frequency pcb board signals of reverse engineering.

4. Generally, parallel wiring can reduce wire inductance, but mutual inductance and distributed capacitance between wires will increase. In order to suppress crosstalk between PCB lines, long-distance parallel wiring should be avoided as much as possible when designing and routing, and the distance between wires should be widened as much as possible. Signal lines should not cross ground and power lines as much as possible.

Setting a grounded line between some signal lines that are very sensitive to interference can effectively suppress crosstalk.

5. As far as possible, the wiring should have the same output current, and the signals in the opposite direction use parallel layout to eliminate the corresponding magnetic field interference.

6. Leads around heating elements or through large currents should avoid using large-area copper foil as much as possible. Otherwise, the copper foil will easily expand and fall off when heated for a long time. When it is necessary to use a large area of copper foil, it is best to use a grid shape, which is conducive to the discharge of volatile gases caused by the heating of the adhesive between the copper foil and the substrate.

7. The diameter of the center hole of the pad is slightly larger than the diameter of the device lead. If the pad is too large, it may form a virtual solder.

8. In the PCB, the unused areas are preferably covered by a large ground plane to provide shielding and increase decoupling capabilities.