Printed Circuit Board Raw Material plays an important role for its electricity performance stability and reliability for electronic device and appliance, which is also has great impact on the process of reverse engineering PCB board;

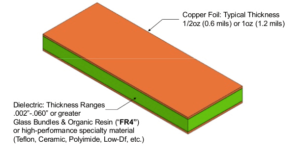

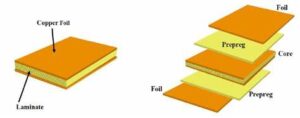

The most used PCB board is FR4, which uses glass fiber cloth as a reinforcing material and epoxy resin as an adhesive.

The most used PCB board is FR4, which uses glass fiber cloth as a reinforcing material and epoxy resin as an adhesive.

The other is the composite substrate CEM1, which is widely used in household appliances and other industries. It uses wood pulp fiber paper or cotton pulp fiber paper as the core material reinforcement, and glass fiber cloth as the surface reinforcement material, both of which are impregnated with flame retardant epoxy Resin. The board is mainly used in single-sided applications. Its mechanical strength is lower than FR4 board, but the price is relatively cheaper and it also has flame retardant properties.

Printed Circuit Board Raw Material plays an important role for its electricity performance stability and reliability for electronic device and appliance, which is also has great impact on the process of reverse engineering PCB board;

The main parameters of PCB material are relative dielectric constant and material loss angle. The combination of the two can express the complex dielectric constant. It is mentioned that the larger the relative dielectric constant, the slower the signal propagation speed in the medium; the larger the material loss angle, the larger the dielectric loss.

Therefore, in the reverse engineering design of high-speed signal PCB, materials with small dielectric constant and material loss angle will be selected as much as possible, and the cost will increase accordingly.

The thickness of copper foil is often expressed in ounces (oz). oz is a unit of mass (everyone knows about gold and silver), and 1oz of copper foil means that 1oz quality (28.35g) of copper foil is evenly spread on 1 square foot area. , Its thickness is 1.37mil, which is about 1.4mil=35um.

The commonly used copper foil materials for circuit boards are mainly divided into rolled copper foil and electrolytic copper foil. The rolled copper foil has tight molecules, smoother surface (conducive to the propagation of high-speed signals), good bending resistance and flexibility, and is not easy to break, so it is generally used For products with bending requirements.