Exploring Philip Computer Tomography Mainboard Chip Level Maintenance has a positive significance for expanding the technical level of Computered Tomography PCB board maintenance and reducing maintenance costs.

At present, Philip Computer Tomography equipment is rapidly and widely popularized in China. County and district hospitals in economic development areas are almost all equipped with CTs of different grades. There are more than one large and medium-sized hospitals, and more than 1500 in one Province alone.

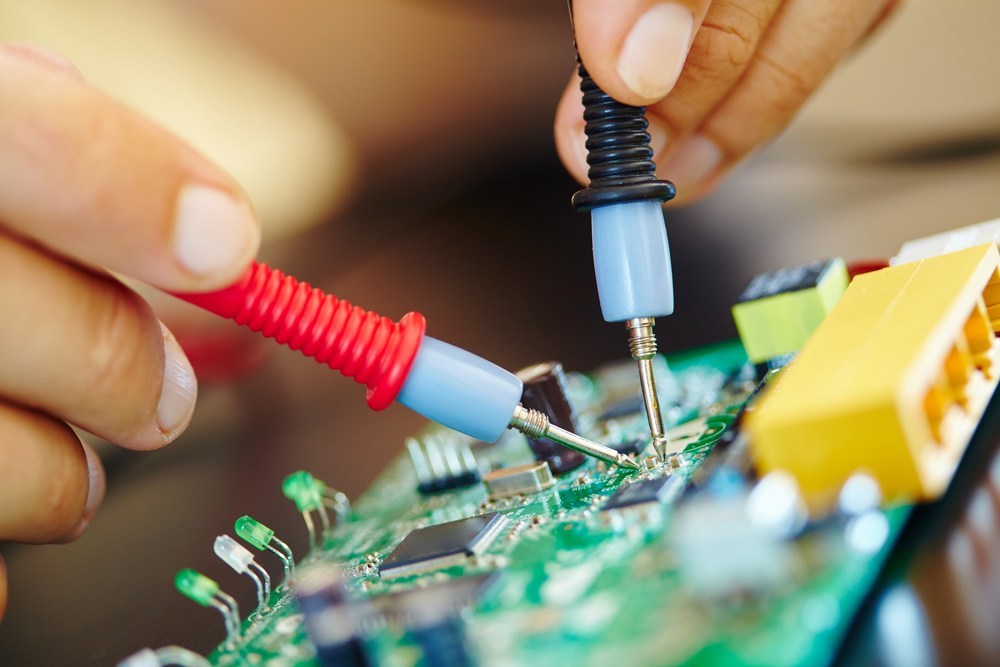

Computer Tomography controller board faulty diagnotise work is becoming more and more heavy, and the maintenance expenditure is considerable. Under normal circumstances, foreign Computer Tomography manufacturers or their repair stations mostly adopt board-level maintenance methods: running procedures and replacing motherboards.

Something happened to the Computer Tomography device mainboard faulty, if the fault occurs, the engineer runs a diagnostic program to find the faulty circuit board for replacement and repair the mainboard fault.

This method is called board-level repair or board replacement, and the defective circuit board is sent back to the company’s local factory for repair.

This kind of maintenance method has a heavy maintenance burden on hospitals. Generally speaking, the damaged CT circuit board is usually not very serious. Except for the large-scale chip burnout caused by the power circuit or high-voltage string signal or low-voltage circuit, it is mostly due to the random quality of individual devices or the randomness of grid pulse interference. The reason is that only a few or individual components are damaged, which has the possibility of repair.