PCB board rework refers to the process of repairing, modifying, or replacing components on a printed circuit board (PCB) after initial assembly. Rework is a critical skill in electronics manufacturing and repair, especially when dealing with high-value boards, prototypes, or small production runs where scrapping a faulty PCB is not an option.

Retrabalho de placas de circuito impresso refere-se ao processo de reparo, modificação ou substituição de componentes em uma placa de circuito impresso (PCB) após a montagem inicial. O retrabalho é uma habilidade crítica na fabricação e reparo de eletrônicos, especialmente ao lidar com placas de alto valor, protótipos ou pequenas séries de produção, onde o descarte de uma PCB defeituosa não é uma opção. Técnicas eficazes de retrabalho de PCB podem restaurar a funcionalidade total, corrigir erros de montagem ou atualizar componentes sem danificar os circuitos adjacentes. No entanto, isso requer ferramentas de precisão, técnicos qualificados e um bom entendimento do comportamento dos componentes e da PCB sob calor e estresse. Técnicas adequadas de retrabalho de placas de circuito impresso (PCB) podem economizar tempo e recursos, prolongar a vida útil do produto e melhorar o rendimento da produção. Quando realizado corretamente, o retrabalho mantém a integridade elétrica e mecânica da PCB

Effective PCB rework techniques can restore full functionality, correct assembly errors, or upgrade components without damaging the surrounding circuitry. However, it requires precision tools, skilled technicians, and a good understanding of component and PCB behavior under heat and stress.

PCB kart yeniden işleme, ilk montajdan sonra baskılı devre kartındaki (PCB) bileşenleri onarma, değiştirme veya değiştirme sürecini ifade eder. Yeniden işleme, özellikle yüksek değerli kartlar, prototipler veya hatalı bir PCB’yi hurdaya çıkarmanın bir seçenek olmadığı küçük üretim serileriyle uğraşırken, elektronik üretim ve onarımında kritik bir beceridir. Etkili PCB yeniden işleme teknikleri, çevredeki devrelere zarar vermeden tam işlevselliği geri yükleyebilir, montaj hatalarını düzeltebilir veya bileşenleri yükseltebilir. Ancak, hassas aletler, yetenekli teknisyenler ve ısı ve stres altında bileşen ve PCB davranışına dair iyi bir anlayış gerektirir. Uygun PCB kartı yeniden işleme teknikleri zamandan ve kaynaklardan tasarruf sağlayabilir, ürün ömrünü uzatabilir ve üretim verimini artırabilir. Doğru şekilde yapıldığında, yeniden işleme PCB’nin elektriksel ve mekanik bütünlüğünü korur ve bu da onu elektronik üretim ve onarımında olmazsa olmaz bir süreç haline getirir.

Common Rework Scenarios

Some typical reasons for rework include:

-

Replacing defective or incorrect components (ICs, capacitors, resistors)

-

Repairing broken traces or pads

-

Fixing cold solder joints or bridges

-

Modifying a design by changing components or adding jumpers

Key Rework Techniques

-

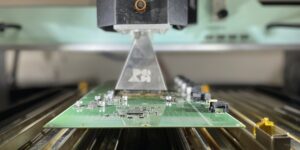

Desoldering Components

Removing components without damaging the pads or vias is essential. Desoldering pumps, braided solder wick, and hot air rework stations are commonly used. For fine-pitch SMD (Surface Mount Device) components, hot air tools with adjustable temperature and airflow are preferred. -

Component Replacement

Once removed, components are replaced using precision tweezers and re-soldered with the appropriate technique—hand soldering for through-hole, or reflow soldering for surface-mount parts. It’s critical to avoid overheating sensitive components during reinstallation. -

Pad and Trace Repair

Damaged copper pads or lifted traces can be restored using circuit repair kits, which include adhesive-backed pads, conductive inks, and fine wire for jumper connections. These repairs require careful surface preparation and insulation. -

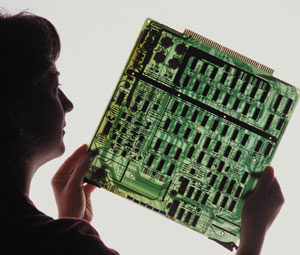

Cleaning and Inspection

After rework, the board must be cleaned (especially from flux residues) using isopropyl alcohol or dedicated PCB cleaning solutions. Visual inspection, X-ray, or AOI (Automated Optical Inspection) ensures that no defects remain.

Conclusion

Przeróbka płytek PCB odnosi się do procesu naprawy, modyfikacji lub wymiany komponentów na płytce drukowanej (PCB) po początkowym montażu. Przeróbka jest kluczową umiejętnością w produkcji i naprawie urządzeń elektronicznych, szczególnie w przypadku płytek o dużej wartości, prototypów lub małych serii produkcyjnych, w których złomowanie wadliwej płytki PCB nie jest opcją. Skuteczne techniki przeróbki płytek PCB mogą przywrócić pełną funkcjonalność, naprawić błędy montażu lub ulepszyć komponenty bez uszkadzania otaczających obwodów. Wymaga to jednak precyzyjnych narzędzi, wykwalifikowanych techników i dobrego zrozumienia zachowania komponentów i płytki PCB pod wpływem ciepła i naprężeń.

Proper PCB board rework techniques can save time and resources, extend product life, and improve production yields. When done correctly, rework maintains the electrical and mechanical integrity of the PCB, making it an essential process in electronics manufacturing and repair.

In the process of great variety of PCB Board Rework, there are multiple ways for selection, generally speaking the decision of choosing a way of PCB Board Rework is not base upon the specific type of the electronic device. however the selection of a proper techniques of PCB Board Rework should be proceed in crossing ways.

en el proceso de gran variedad de retrabajo de la placa PCB, hay múltiples formas de selección, en términos generales, la decisión de elegir una forma de retrabajo de la placa PCB no se basa en el tipo específico del dispositivo electrónico. sin embargo, la selección de técnicas adecuadas de retrabajo de la placa PCB debe realizarse en vías de cruce.

Although there are many ways of PCB Board inspection, in such a complicate and time consuming PCB Board inspection and rework process, the most commonly used way for PCB Board Rework is almost the same, hereby we will introduce a way for PCB Board Rework and Inspection:

1

Instinct Inspection Method, it is a way to apply no electronic device and gadgets, without soldering or de-soldering any electronic components on the PCB board, only through human engineers’ visual inspection, sniffing ability, hearing and touching sensibility to inspect and rework failure converter. and instinctive inspection technique is the most simple way to detect the unfunctioning PCB board, and also this way can also be categorized into with electrical power supply and without electrical power supply.

Instinct Inspection Method of PCB Board Rework

2

Signal Tracking Method is a technique to use single test signal by assistance of detecting device such as oscilloscope, multimeter, etc. from the front part to back part to trace the errors. this method can execute the quantitative examination deeply and locate the area of malfunctions in a relatively short time.

Signal Tracking Method of PCB Board Rework

Rework PCB board is one of our main service categories, the standard procedures is through the root cause and problematic description given by our customer, we will preliminary draw the conclusion about the root cause of failure then customers can ship their malfunctional PCB board to us for reworking!