PCB Board Reverse Engineering Test

Validate concepts

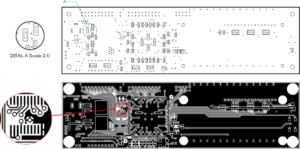

After Prototype has been built according to the PCB Board Layout drawing and Gerber file, list of component extracted through PCB Board reverse engineering technique, testing may be used to validate concepts for function and producibility; prove out production concepts; and demonstrate adequacy to meet user requirements. Testing may not, depending upon a risk assessment, be required for simple items such as nuts and bolts.

PCB Board Reverse Engineering Test

Focus on conformance

Prototype testing may be conducted in accordance with the developed test plans, and should focus on conformance to reliability, such as the PCB Board which has been applied on the harsh environment, high temperature, strong and high frequent vibration, great moisture and salt level, availability for those PCB boards which great amount of components have been phased out from the market and not easy to source, and maintainability for those parts used on industrial or other automation field which is quite expensive and hard to replace requirements; supportability, survivability; human factors; and safety.

Certificate of compliance.

A certificate of compliance should be placed in the candidate file certifying the PCB Board complies with workmanship standards and that all requirements and/or changes have been completed and the prototype is an acceptable replacement for the candidate.