In below articles we would like to introduce some of the PCB Board drilling tips which can help designer not only decrease the production cost but increase the reliability of PCB Board:

The inner diameter of the through hole is required to be 0.2mm (8mil) or more in principle, and the outer diameter is 0.4mm (16mil) or more. In difficult places, it must be controlled to an outer diameter of 0.35mm (14mil);

Tip small assistant: According to the experience, the inner diameter and outer diameter of the commonly used via size of PCB generally follow X*2±2mil (X indicates the inner diameter). For example, a 8 mil inner diameter via can be designed as 8/14 mil, 8/16 mil or 8/18 mil; for example, a 12 mil via can be designed as 12/22 mil, 12/24 mil, 12/26 mil;

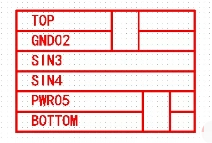

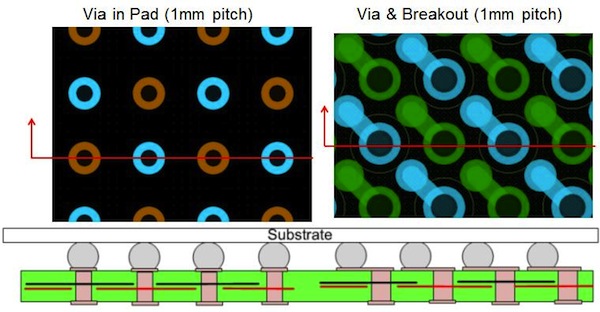

When reverse engineering PCB with BGA footprint recommendations in 0.65mm and above, do not use buried or blind holes, the cost will increase significantly. When using a blind hole, a phase 1 blind hole is generally used (TOP layer – L2 layer or BOTTOM – negative L2). The inner diameter of the via hole is generally 0.1 mm (4 mil) and the outer diameter is 0.25 mm (10 mil). See below Figure.

The via hole cannot be placed on the pad of less than 0402 resistor capacity pad; theoretically, the lead inductance on the pad is small, but when it is produced, the solder paste is easy to enter the via hole, causing the solder paste to be uneven and causing the electronic component to assemble onto the PCB unevenly. Generally recommended spacing is 4-8mil.

via hole cannot be placed on the pad of less than 0402 resistor capacity pad