Post-PC Board shipment inspection

To preclude the replication of defects, the PC Board Reverse Engineering Initial Inspection for possible damage in shipment. sometimes the PC board sent from customers may have the faulty or malfunction problem such as the burn out capacitor, incapable integrated circuit or mis-match oscillators, unshaped terminal block or pin header. we have even found there is abnormal assembly way for some of the electronic components on the PC board which is going to be reversed engineered;

The necessary documentation for control of Government Furnished Equipment (GFE), i.e., Damage Reports or Failed Item Reports (Form DD-1149), should be generated as required. An initial operating test should be performed to ensure the item functions in accordance with established performance specifications.

PC Board Reverse Engineering Initial Inspection

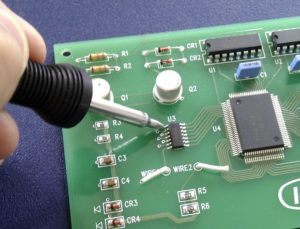

Pre-PC Board disassembly photographs

The PC Board should be photographed prior to and during disassembly in PC Board Reverse Engineering Initial Inspection, in some cases, no other record of the item exists. for printed circuit board, photographed can help engineer to record the orientation, marks and presence/absence of electronic component, mechanical parts, for some of the PC board with DIP insertion assemble way, it could have the possibility to insert on the PC board in reverse or opposite sequence. photograph can effectively help engineer to identify these minor and not-easy-to-find problem to avoid the future mistake in subsequent PC board assembly.

In addition, since the piece-parts will be identified by bagging and tagging, their position in the assembly should be noted.