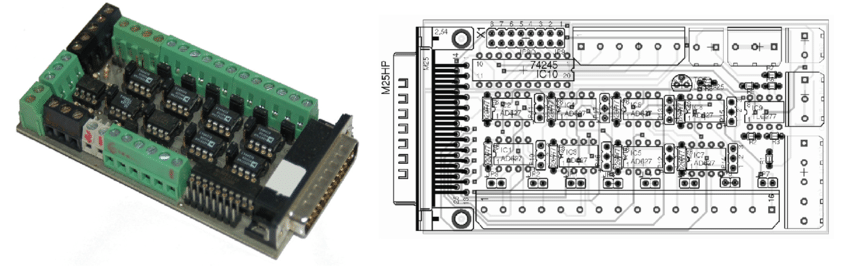

Many PCBs are no longer single-function circuits (digital or analog circuits), but rather a mixture of digital and analog circuits. Therefore, it is necessary to consider the mutual interference between them. through the obselete physical PCB sample, we can Optimize PCB Layout by Reverse Engineering PCB, obtain its original Gerber file and layout diagram. Especially the noise interference on the ground. The frequency of the digital circuit is high, and the sensitivity of the analog circuit is strong. For the signal line, the high-frequency signal line is as far as possible away from the sensitive analog circuit device.

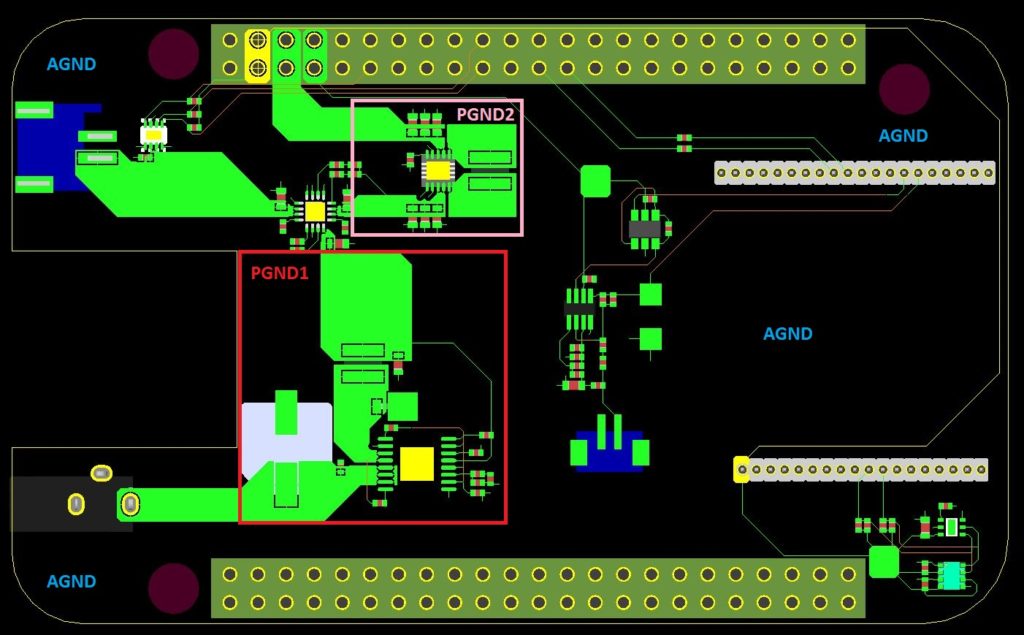

For the ground line, the whole PCB layout drawing has only one node to the outside, so The problem of the number of processing and the common mode must be carried out inside the PCB, and the digital ground and the analog ground inside the board are actually separated from each other, but only at the interface where the PCB is connected to the outside (such as a plug). The digital ground is slightly shorted to the analog ground. Please note that there is only one connection point. There is also no common ground on the PCB, which is determined by the system design.

When wiring the multi-layer printed circuit board, there is not much space left in the signal line layer. If the number of layers is added, the waste will increase the workload and increase the cost. To resolve this contradiction, consider layout PCB board wiring on the electrical (ground) layer. The power layer should be considered first, followed by the ground layer. Because it is best to preserve the integrity of the formation.

In a large area of grounding (electricity), the pins of common components are connected to them, and the treatment of the connecting pins needs to be comprehensively considered. In terms of electrical performance, the pads of the component legs are perfectly connected with the copper surface, but There are some hidden dangers in the soldering assembly of the components. For example, 1st point is welding requires a high-power heater. 2nd is easy to cause a virtual solder joint. Therefore, taking into account the electrical performance and process needs, making a cross-shaped pad, called heat shield, commonly known as thermal pad, so that the possibility of creating a solder joint due to cross-distribution heat during soldering can be greatly reduced. The treatment of the grounding pin of the multi-layer PCB board is the same.