Manual Wire Routing in PCB Board Reverse Engineering is to connect the lines on the already setup point and pad elements. When routing the wires manually, engineer reverse engineering printed circuit board uses a single-color single-pixel line to display a piece of connecting line.

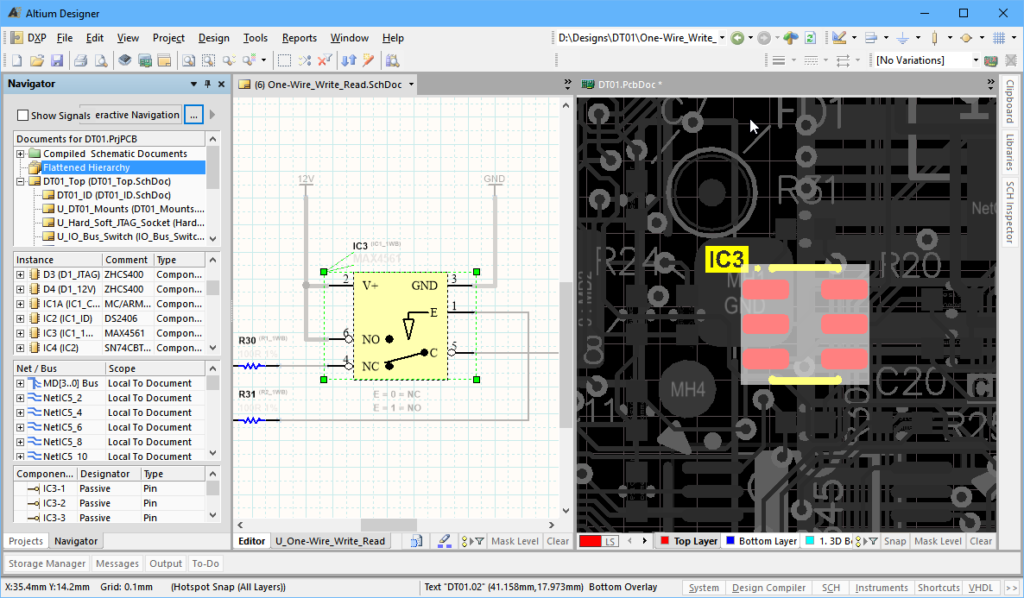

The front and back sides of PCB board can be distinguished by different colors to reduce impact on the base map. The program uses a fuzzy algorithm to capture the line ends and determine the connection status on the physical objectives;

The data-bus bar is used to layout and routing great amount of the parallel wires. Photographic and scanned images of the front and back sides of the double layer PCB do not help solve the intermediate layer conductors of the multilayer printed circuit board reverse engineering.

In fact, as long as the consideration of embedded components on the Printed circuit board can be ignored when reverse engineering it, no matter how many intermediate layers, through simple testing the connection relationship among the elements can be find out. The components and the through holes will be arranged first, and then the wiring and routing is arranged which can reduce the operation of those material in the circuit board reverse engineering, the point element object has the ability to automatically capture the line head.

For the automatic generation technology of the schematic diagram, it mainly solves the problem of component layout and connection. The logic layout diagram is to dispense the passive and negative components in the circuit board reasonably on the same plane, so that the drawn schematic diagram meets the target requirements, and the layout effect will directly affect the quality of the PCB reverse engineering, which is a critical part in the automatic generation of the logic PCB diagram. It is also a problem that people have been concerned about and have not solved very well.