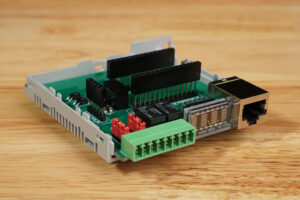

Machine control systems are the heart of industrial automation, and PLC (Programmable Logic Controller) PCB boards play a critical role in ensuring their seamless operation. However, over time, these electronic circuit boards may become obsolete or damaged, leading to operational downtime. In such scenarios, machine control PLC PCB board reverse engineering offers a solution that allows for the replication, restoration, and even modification of existing designs, ensuring continued functionality and reliability.

Machine control systems are the heart of industrial automation, and PLC (Programmable Logic Controller) PCB boards play a critical role in ensuring their seamless operation. However, over time, these electronic circuit boards may become obsolete or damaged, leading to operational downtime. In such scenarios, machine control PLC PCB board reverse engineering offers a solution that allows for the replication, restoration, and even modification of existing designs, ensuring continued functionality and reliability.

The Reverse Engineering Process

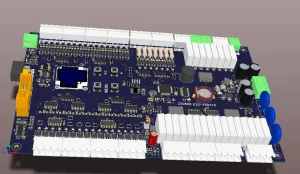

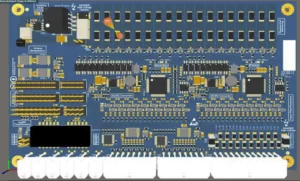

Reverse engineering involves the meticulous disassembly and analysis of a PCB board to extract crucial data such as Gerber files, schematic diagrams, layout drawings, and BOM (Bill of Materials) lists. Engineers then use this information to duplicate or clone the original design, or even improve upon it for enhanced performance.

Key files, including Gerber data and CAD files, provide a detailed representation of the PCB layout, pinpointing the exact placement of components and traces. The netlist offers additional insights into the connectivity of components, ensuring the new electronic circuit board operates correctly.

Los archivos clave, incluidos los datos Gerber y los archivos CAD, proporcionan una representación detallada del diseño de la placa de circuito impreso, lo que indica la ubicación exacta de los componentes y las pistas. La lista de conexiones ofrece información adicional sobre la conectividad de los componentes, lo que garantiza que la nueva placa de circuito electrónico funcione correctamente.

Benefits of PLC PCB Reverse Engineering

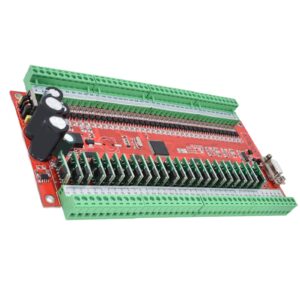

- Restoration and Recovery: In cases where a PCB board is no longer available or a schematic has been lost, reverse engineering allows for the restoration or recovery of the original design. This is particularly useful when trying to replace obsolete equipment in critical systems.

-

Restauração e Recuperação: Em casos em que uma placa PCB não está mais disponível ou um esquema foi perdido, a engenharia reversa permite a restauração ou recuperação do design original. Isso é particularmente útil ao tentar substituir equipamentos obsoletos em sistemas críticos.

Replication and Cloning: If a PLC board is malfunctioning or cannot be sourced, reverse engineering enables engineers to reproduce or clone the exact PCB, preventing expensive downtime and production delays.

- Modification and Remanufacture: Reverse engineering also allows for modifications to existing PCB boards, such as enhancing performance or adapting to new control systems, leading to more efficient and adaptable machines.

The Future of Machine Control Systems

Machine control systems depend on the accuracy and reliability of their electronic circuit boards, and PLC board reverse engineering is crucial for maintaining these systems. By replicating or modifying existing designs, businesses can ensure that their machinery continues to operate smoothly, without the high costs and time delays associated with sourcing new, custom-made parts.

Makine kontrol sistemleri elektronik devre kartlarının doğruluğuna ve güvenilirliğine bağlıdır ve PLC kartı tersine mühendisliği bu sistemlerin bakımı için çok önemlidir. İşletmeler mevcut tasarımları kopyalayarak veya değiştirerek, makinelerinin yeni, özel yapım parçaların tedarik edilmesiyle ilişkili yüksek maliyetler ve zaman gecikmeleri olmadan sorunsuz bir şekilde çalışmaya devam etmesini sağlayabilir.

In conclusion, machine control PLC PCB board reverse engineering is an essential service that offers a range of benefits, from cloning and restoring outdated designs to remanufacturing more efficient, modern PCB boards. It ensures continuity and longevity for industrial systems, making it an indispensable tool in today’s manufacturing world.