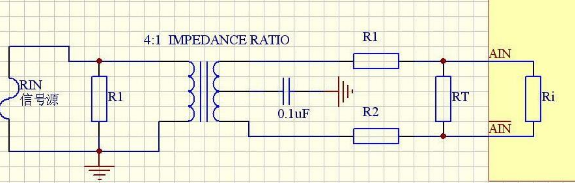

PCB Reverse Engineering Impedance Matching is a suitable way to match a signal source or transmission line to a load. According to the access method, the impedance matching has two modes: serial and parallel. According to the frequency impedance matching of the signal source, it can be divided into low frequency and high frequency.

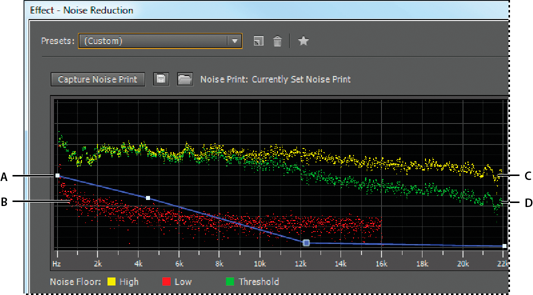

1st of all is High frequency signals generally use serial impedance matching in PCB Reverse engineering. The resistance of the serial resistor is 20~75Ω. The resistance value is proportional to the signal frequency and inversely proportional to the PCB trace width and length. In embedded systems, when the signal frequency is greater than 20M, the serial matching resistor should be added when the PCB trace length is greater than 5cm, such as the clock signal, data and address bus signal in the system. There are two functions of serial matching resistors:

Reduce high frequency noise and edge overshoot. If the edge of a signal is very steep, it contains a lot of high-frequency components, which will cause radiation interference, and it is also prone to overshoot. The series resistor and the distributed capacitance of the signal line and the load input capacitance form an RC circuit, which reduces the steepness of the signal edge.

Reduce high frequency reflection and self-oscillation. When the frequency of the signal is high, the wavelength of the signal is very short. When the wavelength is short compared with the length of the transmission line, the superposition of the reflected signal on the original signal will change the shape of the original signal. If the characteristic impedance of the transmission line is not equal to the load impedance (ie, it does not match), a reflection will occur at the load end, causing self-oscillation. The low frequency signal of the trace inside the PCB board can be directly connected and this point can be effectively avoid by reverse engineering PWB schematic. Generally, no serial matching resistor is needed.