With the rapid development of the mobile phone, electronics and communications industries, and the continuous growth and rapid growth of the Printed circuit board industry, the requirements for the number of layers, weight, precision, materials, color, and reliability of components are increasing, as a result of that, the importance of Identify Printed Circuit Board Quality is taking a indispensible effect in the whole.

However, due to fierce market price competition, plus the cost of PCB board materials is on the rise. More and more manufacturers are monopolizing the market at low prices in order to enhance their core competitiveness. However, behind these ultra-low prices, the material cost and process cost are reduced, but the device is usually prone to cracks, scratches, bow/twist and the comprehensive factors such as precision and performance are not up to standard, seriously affecting the solderability and reliability of the electronic products used.

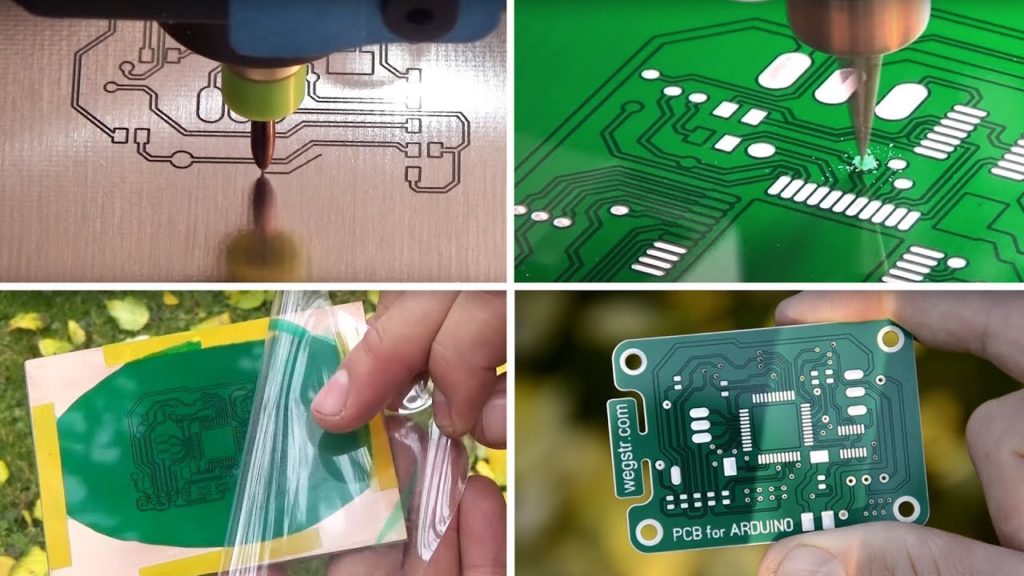

Faced with a variety of Printed circuit boards on the market, the quality of printed circuit boards can be determined from two aspects; the first method is to judge from the appearance, and the other is to judge from the quality specifications of the PCB board itself.

The method of identifying whether the printed circuit board is good or bad: First: distinguishing the appearance of the circuit board. Under normal circumstances, the appearance of the PCB circuit board can be analyzed and judged through three aspects;

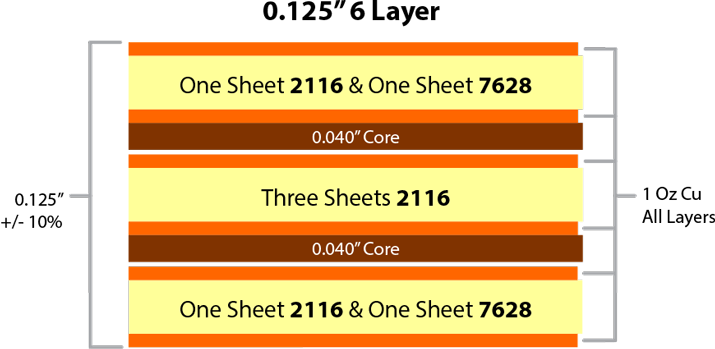

1. The standard rule of size and thickness. The thickness of PCB board to the standard board is different, and the customer can measure and check the thickness and specifications according to their own products.

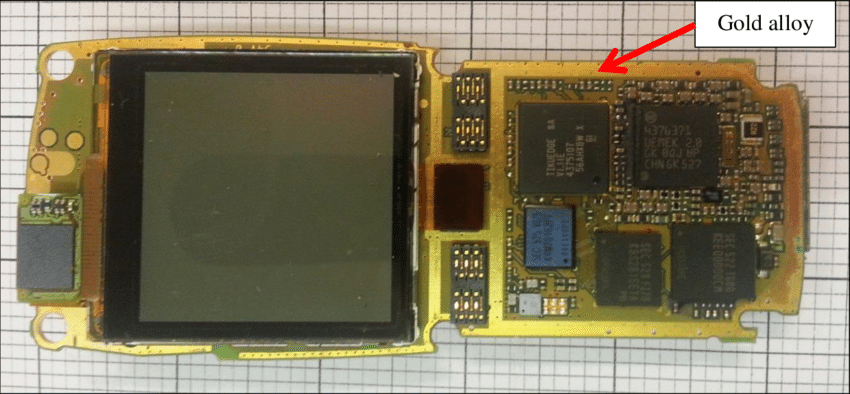

2, light and color. The external circuit board has ink coverage which call solder resist, and can play the role of insulation. If the color of the board is not bright, there is less ink, and the insulation features of PCB board itself is not good.

3. The appearance of the weld. Due to the large number of components on the circuit board, if the welding is not good, the circuit board with that the parts are easy to fall off seriously which will affects the welding quality of the circuit board, and the appearance is not good. It is very important to carefully identify the soldering connection between boards and component’s pin.