PCB prototyping means that after the PCB reverse engineering, engineer will conducts small quantity trial production order to the PCB manufacturer. As a matter of fact, There is no specific requirement for the quantity of PCB prototype production. Design engineer should place order to produce PCB prototypes before mass production to verify if PCB schematic diagram, layout drawing and BOM (Bill of material) is conformed with the physical PCB sample. So How To Judge PCB Prototyping Quality? Normally we go from below 6 aspects:

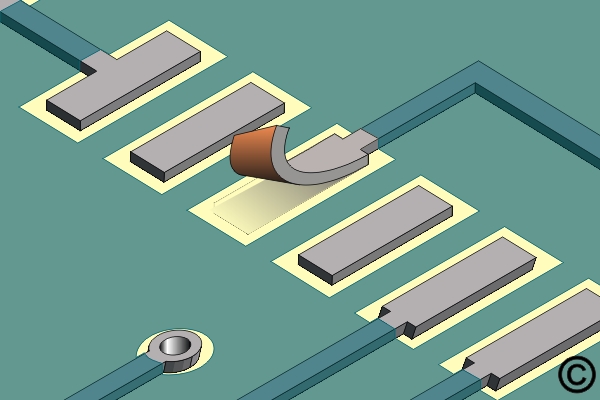

1 The copper foil is not easy to fall off under high temperature environment when soldering the component lead onto it;

copper foil is not easy to fall off under high temperature environment when soldering the component lead onto it

2 The track thickness, line spacing and line width of the track meet the PCB reverse engineering requirements to prevent the line from short circuit and open circuit;

3 PCB circuit board has no additional electromagnetic radiation;

4 In the PCB circuit board manufacturing process, the high temperature, high humidity and other special environments are taken into consideration;

5 The copper surface is not easily oxidized which will caused the life of the oxidized circuit board is greatly shortened.

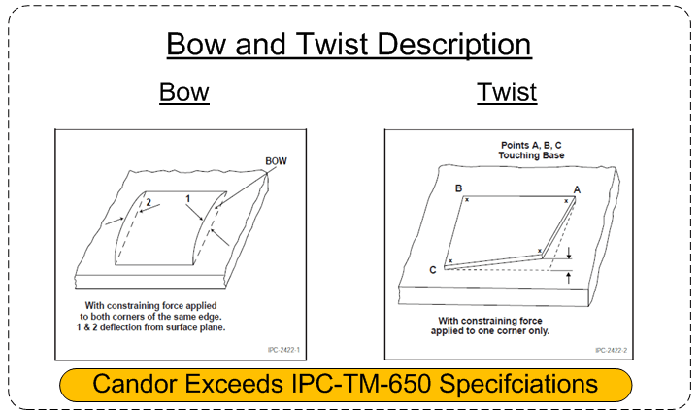

6 Reasonable deformation error, nowadays it is mechanized installation, the hole position of the circuit board and the deformation error of the circuit board design should be within the allowable range.

Combine the above 6 points to measure the quality of the PCB sample, and judge whether the quality is good or not. At present, there are countless PCB factories on the market. It is recommended that users should polish their eyes in the process of selection. On the basis of a certain understanding of the PCB circuit board, the manufacturer’s choice should be made to prevent being deceived.