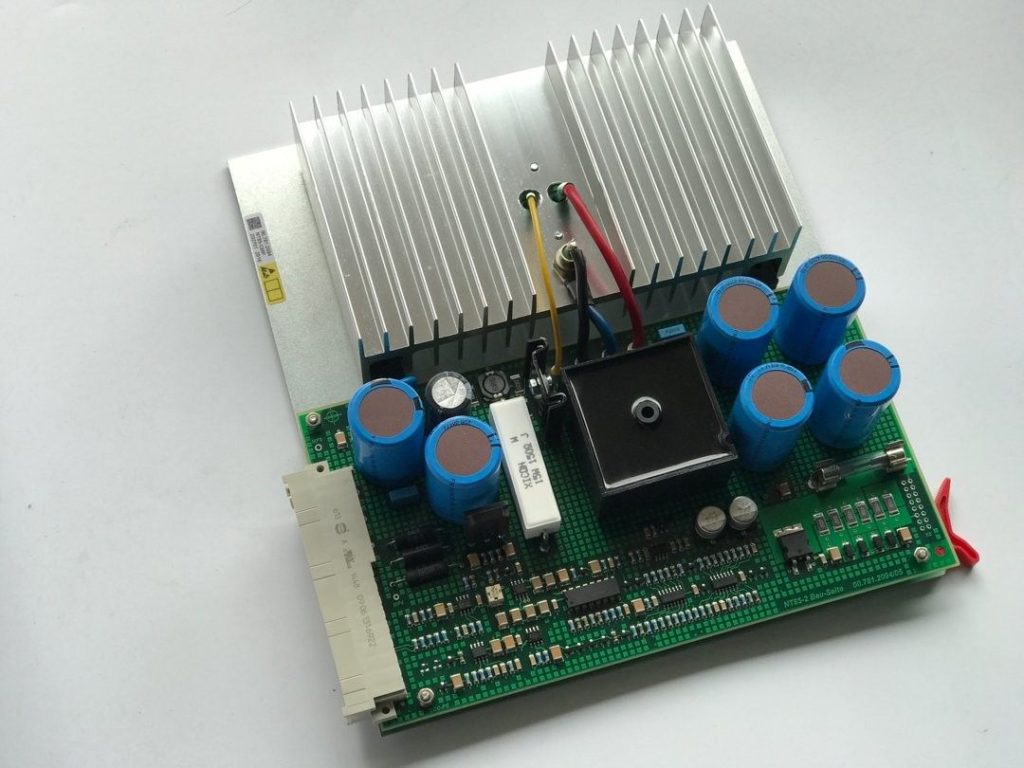

For Heidelberger SM52 SM74 Power Supply Board Repairing Repairing, because the circuits are hung on the bus, there is no clear subordinate relationship. Therefore, it is more difficult to maintain than other motor boards. The following only focuses on the static measurement method of control cards. The maintenance mainly follows the following steps.

Step 1: Use a multimeter to check if there is a short circuit between power and ground. The inspection method is: find a 5V power supply chip and measure two points on the diagonal (such as a 14-pin chip, measure 7 and 14 pins. A 16-pin chip, measure 8 and 16 pins). If there is no short circuit between the two points, the power supply is working normally. If a short circuit occurs, you need to find the cause through investigation.

The power supply board is the basis of Heidelberger Offset printing machine. Only when the power supply works normally, can we talk about the application of subsequent circuits. Therefore, the measurement of the power supply is very important, and it is also a step that is particularly easy to be ignored by maintenance personnel.

Step 2: Use a multimeter to measure the diode and observe whether it works normally. Under normal circumstances, the positive and negative poles are measured with a resistance switch. The positive phase is measured from tens to several hundred ohms, and the reverse phase is measured from one thousand to several thousand ohms. Generally, diodes are damaged due to excessive current in the circuit causing the diode to be broken down.

Step 3: Use a multimeter resistance switch to measure the capacitance to see if there is a short circuit or an open circuit. If so, it means that there is a problem with this part of the circuit. The next step is to determine whether there is a problem with the component itself or with the circuit connected to it. The method is to solder a leg of the suspect component to see if the component is open or disconnected. This allows you to determine the problem in one step.

Step 4: Also use a multimeter to measure the integrated circuits, transistors, and resistors on the Heidelberger SM52 SM74 Power Supply Board to see if they meet their own logic performance. If the circuit board includes a bus structure, generally there will be pull-up resistors on the bus. The measurement of the resistance array is a very important step, and the quality of the chip hanging on the bus can be initially checked by resistance array quality, all the values of the electronic parts over the power supply board can be obtained through PCB reverse engineering service by preparing Bill of Material (BOM) documents.