When execute Heidelberger ESK Circuit Board Recovery, there are many methods to choose from, usually not only based on a certain fault situation of specific electronic equipment, selecting a suitable test and repair method, often a fault that requires cross-combination. Choose from several methods.

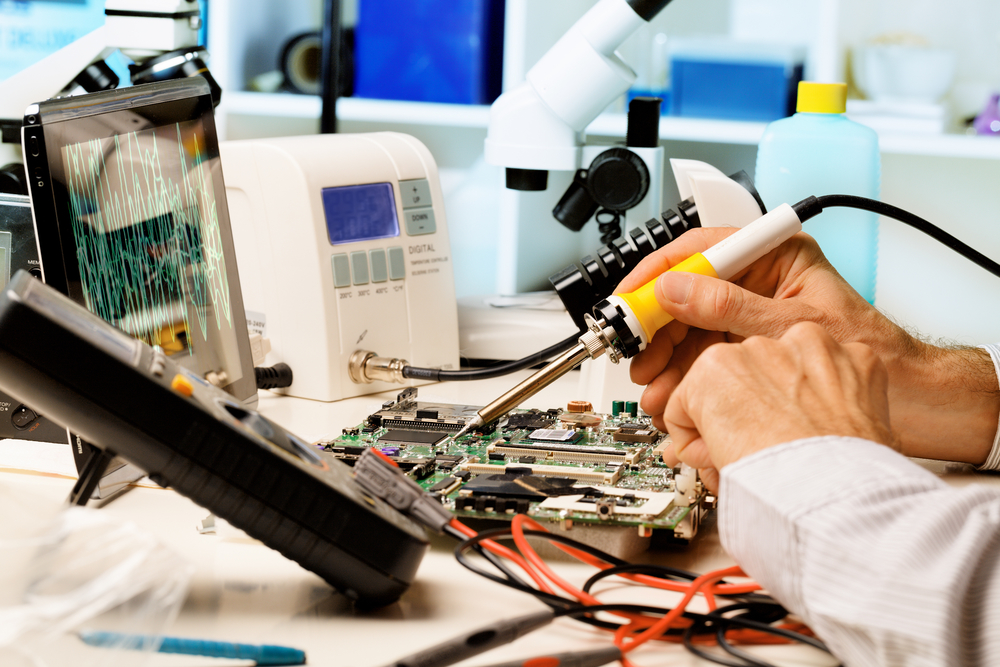

Although there are many kinds of printed circuit board test and repair methods, in a variety of circuit board test and recovery processes, the generally used test and rework methods are basically the same. The following describes the basic circuit board recovery methods of electronic equipment for readers to choose when conducting PCB board test and repair work, or to refer to when combining and selecting.

I. Intuitive inspection method: This method refers to the use of human intuition-vision, smell, hearing, and touch to check the failure of the controller card to be reworked without using any instruments and equipment or soldering any circuit components. A way. Intuitive inspection is the simplest method for equipment failure. This method can be divided into two types: power-on inspection method and power-off inspection method.

Second, the signal tracking method: This method uses a single test signal, with the help of test equipment (such as oscilloscopes, electronic voltmeters, etc.), from front to back to check step by step (tracking) alongside the circuitry pattern of PCB which can be tracked by PCB board layout extracted by PCB reverse engineering. This method can deeply and quantitatively check the PCB board circuitry pattern at all levels, and can quickly determine the fault location.

Third is signal injection method: This method uses different output signals from external signal sources as known test signals, and uses the terminal indicator of the electronic device under test to indicate the test results. During the inspection, according to the specific requirements, select the corresponding signal source to obtain the known signals of different indicators;