Engineer needs to pay attention to Failed Electronic Circuit Card Maintenance Order to find the shortest path to solve the problem, avoid random dismantling or desoldering which will cause the unsuccessful of motherboard maintenance and the failure will expand to more blocks or positions;

Control board reworking is like a doctor seeing a doctor, but also paying attention to “looking and asking.”

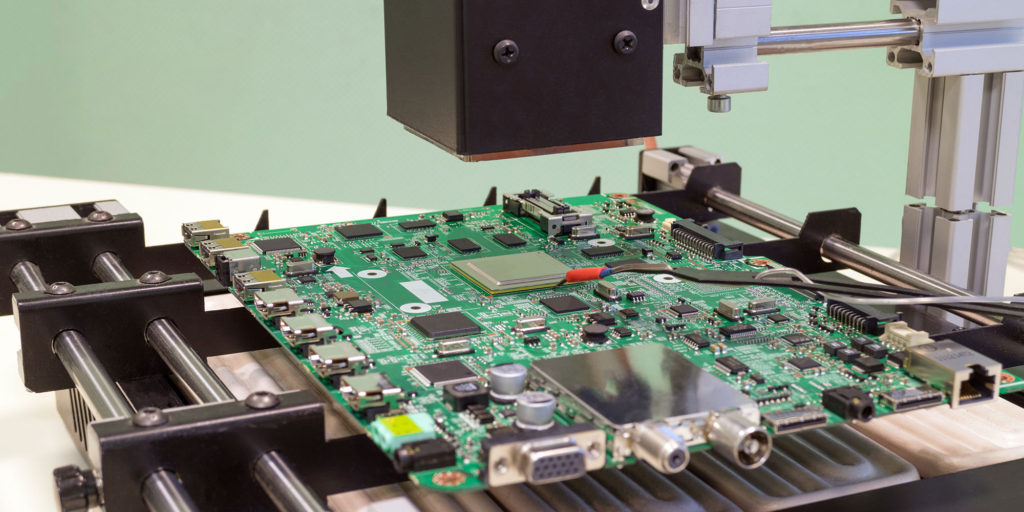

“Look” is to check the appearance of the faulty controller circuit card, to see if there are obvious signs of damage, whether the components are burned or cracked, whether the circuit board is disconnected or leaked due to corrosion, whether the capacitor is leaking, and there is no obstrusion coming out from the top of capacitor;

“Smell” with your nose and smell if there is something burning, where does it come from;

“Ask” is very important. It is necessary to ask the parties in detail about the situation at the time of the equipment failure, and to infer the possible fault location or component from the situation;

“Cut” refers to the use of certain testing equipment such as controller board handheld inspection terminal, divided into two cases of power on and off, check the circuit parts or components of the resistance value, voltage, waveform, etc., the quality of the circuit board comparison test, observe the parameters and other differences.

In fact, there are many faults that you can solve without even using the multimeter, and even in the absence of circuit diagram of circuit board;