Electronic Multilayer PCB Boards are generally defined as high-level multi-layer circuit boards with 10 layers to 20 layers or more, which are more difficult to process than traditional multi-layer circuit boards, and have high quality and reliability requirements. They are mainly used in communication equipment, high-end servers, and medical electronics, aviation, industrial control, military and other fields.

In recent years, the market demand for high-level Electronic Multilayer PCB Board in application communications, base stations, aviation, military and other fields is still strong, and with the rapid development of China’s telecommunication equipment market, the market prospects for high-level PCB boards are optimistic.

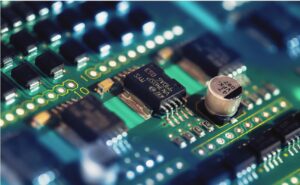

multilayer pcb board reverse engineering and manufacturing

At present, domestic PCB manufacturers that can mass-produce high-level circuit boards mainly come from foreign-funded enterprises or a few domestic-funded enterprises. The production of multi-layer circuit boards not only requires high investment in technology and equipment, but also requires the accumulation of experience of technicians and production personnel.

electronic multilayer printed circuit board cloning

At the same time, the customer certification procedures for importing high-level printed circuit boards are strict and cumbersome, so the threshold for high-level circuit boards to enter the enterprise is high, and the realization of industrial The production cycle is longer. The average number of PCB layers has become an important technical indicator to measure the technical level and product structure of PCB companies. This paper briefly describes the main processing difficulties encountered in the production of high-level circuit boards, and introduces the control points of key production processes of high-level circuit boards for your reference.