The main factors considered in the Cloning Multilayer PCB Board Laminated Structure are the heat resistance of the material, the withstand voltage, the amount of glue filling and the thickness of the dielectric layer, etc. The following main principles should be followed.

Cloning Multilayer PCB Board Laminated Structure

(1) Prepreg and core board manufacturers must be consistent. In order to ensure the reliability of PCB, all layers of prepreg should avoid using single 1080 or 106 prepreg (except customers have special requirements). If the customer has no dielectric thickness requirements, the thickness of the dielectric between each layer must be guaranteed according to IPC-A-600G ≥ 0.09mm.

(2) When the customer requires high TG sheet, the core board and the prepreg must use the corresponding high TG material.

(3) If the inner layer substrate is 3OZ or above, use prepreg with high resin content, such as 1080R/C65%, 1080HR/C 68%, 106R/C 73%, 106HR/C76%; but try to avoid all use of 106 high-resin prepreg and the electronic pcb card structure is reversed to prevent the overlapping of multiple 106 prepregs. Because the glass fiber yarn is too thin, the glass fiber yarn collapses in the large base material area, which affects the dimensional stability and the delamination of the explosion on printed circuit board.

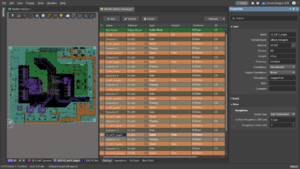

clone multilayer mainboard schematic and gerber file

(4) If the customer has no special requirements, the thickness tolerance of the interlayer dielectric layer is generally controlled by +/-10%. For the impedance plate, the dielectric thickness tolerance is controlled by the IPC-4101 C/M class tolerance. If the impedance influencing factor is related to the thickness of the substrate If relevant, the sheet tolerances must also be in accordance with IPC-4101 Class C/M tolerances.