Many people see the chip-scale BGA package as a viable solution to the space constraints required by high density Printed circuit board on the portable electronics, while meeting the higher functionality and performance requirements of these products. Cloning High Density Printed Circuit Board for portable products should be an assembly process.

Performance and reliability are top priorities when Cloning High Density Printed Circuit Board for today’s value-driven markets. In order to compete in this market, developers must also pay attention to the efficiency of assembly, because it can control manufacturing costs. Technological advances and increasing complexity of electronic products are creating a need for Higher Density Printed Circuit Board manufacturing methods.

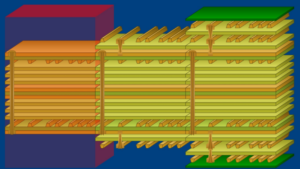

When designing integrated circuits, ICs that require surface mount, fine pitch, and vector packaging, higher density boards with thinner line widths and tighter spacing may be required. However, looking to the future, some companies that are already supplying micro-bypass holes and serial assembly boards are investing heavily to expand their capabilities.

These companies recognize the current trend of portable electronics for smaller packages. The communications and personal computing products industry alone is enough to lead the global market.

Developers of high-density electronics are increasingly challenged by several factors: physics, tighter pin spacing on complex components, financial resources, placement must be precise, and the environment. Many plastic packages absorb moisture, causing assembly processing The rupture.

Physical factors also include the complexity of the installation process and the reliability of the final product. Further financial decisions must consider how the product will be manufactured and assembled with equipment efficiency.

Fragile pin assemblies, such as 0.50 and 0.40mm / 0.020″ and 0.016″ pitch SQFP shrink quad flat packs, may be used to assemble an expert in maintaining a consistent assembly process. The most successful development plans are High Density Printed Circuit Board cloning guidelines and process-certified pad geometries that have been certified for process certification.