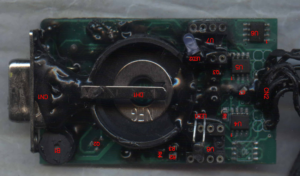

Cloning Automation PCB Board Component Placement Drawing process is both science and art, requiring strategic consideration of the major components available on the pcb board. While the reverse engineering printed circuit board process can be challenging, the way you place your electronic components will determine how easy your electronic pcb card will be to re-manufacture, and how well it will meet your original design requirements.

While there is a general order for component graphics generation such as sequentially placing connectors, printed circuit board mounts, power circuits, precision circuits, critical circuits, etc., there are specific guidelines to keep in mind, including:

Cloning Automation PCB Board Component Placement Drawing

Orientation – Ensuring that similar components are oriented in the same direction will contribute to an efficient and error-free soldering process.

Placement – Avoid placing smaller components behind larger components, which may cause placement problems due to soldering of larger components.

Copying Automation PCB Board Component Placement Drawing

Organization – It is recommended to place all surface mount (SMT) components on the same side of the pcb board when reverse engineering and all through hole (TH) components on top of the circuit board to minimize assembly steps. One final PCB design guideline to note – that when using mixed technology components (both through-hole and surface mount components), the manufacturer may require additional processes to assemble the board, which will add to your overall cost.

Automatización de la clonación Placa de circuito impreso Plano de colocación de componentes