Bellco Dialysis Machine CPU Control Board Rework happens after the malfunctions of whole device is used for a period of time, a large amount of dust will be adsorbed on the surface of the Machine CPU Control Board. This dust will cause the components on the circuit board to fail to dissipate heat, resulting in abnormal work and even damage, especially on some chip pins on the printed circuit board. If it does, it will cause the chip to work unstable, or even cause a short circuit to burn the integrated chip.

The various input and output connectors on the controller circuit board are also often oxidized, resulting in poor contact. Therefore, it is necessary to regard cleaning dust and rust removal of the connectors as a commonly used method to rework controller board, and it has been viewed as a conventional method to eliminate these simple interferences, which is also beneficial to observe other conditions on the circuit board. Although this method is simple, it is really necessary.

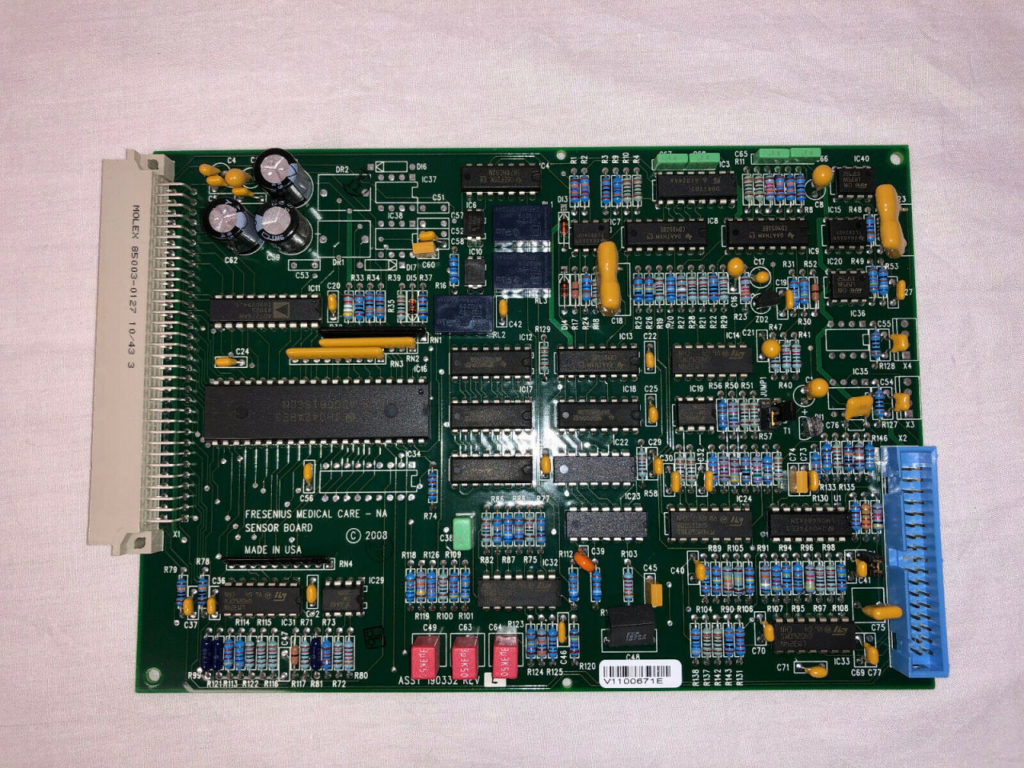

It can also be used as a means of regular machine mainboard maintenance. The following is a typical case I encountered in my work: The Bellco hemodialysis machine turned on with a black screen and beeping. Check all the connections of the CPU controller board and find that the connectors are not oxidized, also inspect the schematic diagram of CPU controller board to figure out the electrical connection scheme. Check the CPU board and find that there is a lot of dust on the board. After cleaning with a brush and a vacuum cleaner, restarting is still not stable.

So remove the CPU board, carefully clean the dust on the circuit board, especially between the pins of the components, with alcohol, blow it back and reinstall it. The machine has been turned on for many times and the test is normal, and the fault of Bellco Dialysis Machine CPU Control Board has been reworked.