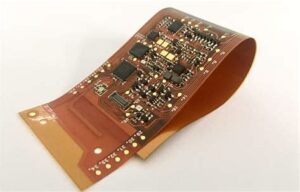

Trackwise develops flexible circuit boards that can be cloned in unlimited lengths. Trackwise chief executive Philip Johnston said the use of long, flexible printed circuits on aircraft could help address the weight and space challenges of traditional wiring harnesses and provide a great meaningful purpose for Automobile Flexible Circuit Board Cloning;

Flex offers a lighter solution that takes up less space and has the potential to distribute control electronics onto “smart wiring harnesses” while Automobile Flexible Circuit Board Cloning can help to recreate the PCB board’s gerber file, layout drawing, BOM list and schematic diagram

Trackwise’s Long Flex PCB boards are used in temperature and voltage monitoring circuits for electric vehicle battery packs. Replacing traditional wiring harnesses, Flex offers a lighter solution that takes up less space and has the potential to distribute control electronics onto “smart wiring harnesses” while Automobile Flexible Circuit Board Cloning can help to recreate the PCB board’s gerber file, layout drawing, BOM list and schematic diagram;

“As the battery pack of an electric vehicle is a primary energy source, the control and monitoring of the individual cells and modules is critical. This is not only for safety reasons, but also for maximum performance efficiency and maximum range. Flexible Printed Circuits (FPCs) ) are ideal for battery module control and monitoring circuits,” Johnston said. “Their compact size not only greatly improves space, but also reduces weight compared to bulky wiring harnesses.”

the use of long, flexible printed circuits on aircraft could help address the weight and space challenges of traditional wiring harnesses and provide a great meaningful purpose for Automobile Flexible Circuit Board Cloning;

He added: “Trackwise’s roll-to-roll technology is already being used to manufacture FPCs for high- and low-voltage circuits for EV battery modules and packs, reducing assembly time, BOM cost, and saving space and weight.”