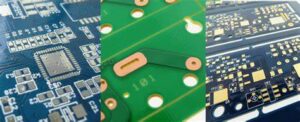

On the printed circuit board, copper is used to interconnect the components on the substrate. Although it is a good conductor material for forming the pattern of the conductive path of the printed circuit board, it will also be exposed to the air for a long time. It is easy to lose luster due to oxidation, and lose weldability due to corrosion, that is the main reason Why we need to have Surface Treatment over PCB Board;

Why we need to have Surface Treatment over PCB Board

Therefore, various technologies must be used to protect copper traces, vias, and plated through holes. These technologies include organic paint, oxide film, and electroplating.

Organic paint is very simple to apply, but it is not suitable for long-term use due to changes in its concentration, composition and curing cycle. It even leads to unpredictable deviations in solderability. Oxide film can protect the circuit from corrosion, but it cannot maintain solderability.

Electroplating or metal coating processes are standard operations to ensure solderability and protect circuits from corrosion, and play an important role in the manufacture of single-sided, double-sided, and multilayer printed circuit boards.

In particular, plating a layer of solderable metal on the printed wire board has become a standard operation to provide a solderable protective layer for the copper printed tracks.