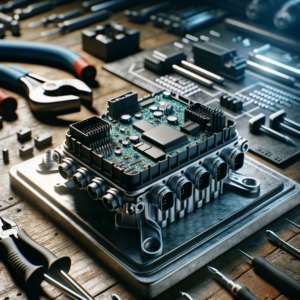

Reverse engineering an engine control unit (ECU) PCB board is a critical process used to recreate or restore functionality in situations where the original design files or components are no longer available due to obsolescence or production discontinuation. This involves duplicating the design and functionality of the PCB board to ensure the continued operation of essential systems, especially for old or hard-to-find multilayer boards.

Reverse engineering an engine control unit (ECU) PCB board is a critical process used to recreate or restore functionality in situations where the original design files or components are no longer available due to obsolescence or production discontinuation. This involves duplicating the design and functionality of the PCB board to ensure the continued operation of essential systems, especially for old or hard-to-find multilayer boards.

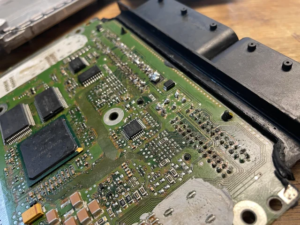

The process begins with detailed analysis of the ECU’s circuit board to extract critical information such as the layout drawing, BOM list (Bill of Materials), and component list. Each layer of the multilayer PCB board is carefully inspected to map out the traces, connections, and part placements. Using tools to recreate the net-list and schematic diagram, engineers gain a functional understanding of the board’s design. This ensures that the recreated electronic board is a precise replica of the original.

प्रक्रिया ECU के सर्किट बोर्ड के विस्तृत विश्लेषण से शुरू होती है ताकि लेआउट ड्राइंग, BOM सूची (सामग्री का बिल) और घटक सूची जैसी महत्वपूर्ण जानकारी निकाली जा सके। मल्टीलेयर PCB बोर्ड की प्रत्येक परत का सावधानीपूर्वक निरीक्षण किया जाता है ताकि ट्रेस, कनेक्शन और पार्ट प्लेसमेंट का पता लगाया जा सके। नेट-लिस्ट और योजनाबद्ध आरेख को फिर से बनाने के लिए उपकरणों का उपयोग करके, इंजीनियरों को बोर्ड के डिज़ाइन की कार्यात्मक समझ प्राप्त होती है। यह सुनिश्चित करता है कि पुनः निर्मित इलेक्ट्रॉनिक बोर्ड मूल की एक सटीक प्रतिकृति है

To achieve recovery or duplication, reverse engineering also involves creating a Gerber file. This file is essential for PCB manufacturing, containing detailed information about each layer of the PCB board. Additionally, a pick-and-place orientation file is generated to guide the placement of components, ensuring the rebuilt ECU performs exactly like the original. For systems where parts are obsolete or unavailable, alternatives are identified and integrated into the recreated design.

Para lograr la recuperación o duplicación, la ingeniería inversa también implica la creación de un archivo Gerber. Este archivo es esencial para la fabricación de PCB, ya que contiene información detallada sobre cada capa de la placa PCB. Además, se genera un archivo de orientación de selección y colocación para guiar la colocación de los componentes, lo que garantiza que la ECU reconstruida funcione exactamente como la original. Para los sistemas en los que las piezas están obsoletas o no están disponibles, se identifican alternativas y se integran en el diseño recreado.

This approach is particularly valuable for ECUs in vehicles or machinery where the original circuit boards are no longer produced. By cloning or replicating the ECU PCB board, companies can maintain and repair critical systems, extending the lifespan of equipment and avoiding costly replacements.

Reverse engineering the ECU PCB board is also essential for troubleshooting and performance enhancement. By analyzing and recreating the board, engineers can identify design flaws, optimize performance, or adapt the system for new applications.

In conclusion, reverse engineering an engine control unit PCB board involves copying, restoring, and recreating the original design using advanced tools and techniques. By generating layout drawings, Gerber files, and BOM lists, it is possible to replicate hard-to-find or discontinued multilayer circuit boards. This process not only supports the recovery of old or obsolete systems but also ensures continued functionality in critical applications while preserving valuable electronic designs.

ECU PCB kartının tersine mühendisliği, sorun giderme ve performans geliştirme için de önemlidir. Mühendisler kartı analiz edip yeniden oluşturarak tasarım kusurlarını belirleyebilir, performansı optimize edebilir veya sistemi yeni uygulamalara uyarlayabilir.

Sonuç olarak, bir motor kontrol ünitesi PCB kartının tersine mühendisliği, gelişmiş araçlar ve teknikler kullanılarak orijinal tasarımın kopyalanmasını, geri yüklenmesini ve yeniden oluşturulmasını içerir. Düzen çizimleri, Gerber dosyaları ve BOM listeleri oluşturarak, bulunması zor veya üretimi durdurulmuş çok katmanlı devre kartlarını çoğaltmak mümkündür. Bu süreç yalnızca eski veya modası geçmiş sistemlerin kurtarılmasını desteklemekle kalmaz, aynı zamanda değerli elektronik tasarımları korurken kritik uygulamalarda işlevselliğin devam etmesini sağlar