Embedded Electronic Circuit Board Cloning have different hardware forms, with CPUs ranging from simple 4-bit/8-bit micro-controllers to 32-bit ARM processors and other special-purpose ICs. In addition, according to the different needs of the product, the peripheral circuits are also different. In every Embedded Electronic Circuit Board cloning process, it is necessary to choose the most suitable solution based on actual needs and considering various factors.

Embedded Electronic Circuit Board Cloning have different hardware forms

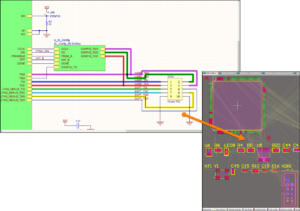

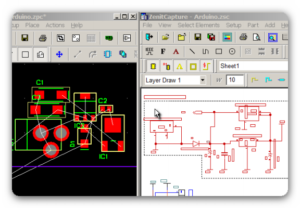

After the printed circuit board design drawing cloning plan is determined, we can carry out related PCB board redesign work. The principle design mainly includes the overall system design and detailed design, and finally recreate detailed design documents and PCB board schematics.

Principle design and PCB design are one of the two most important tasks for designers. In the principle design process, we need to plan hardware internal resources, such as system storage space, and the implementation of various peripheral circuit modules. In addition, the main peripheral circuits of the system, such as power supply, reset, etc., also need to be carefully considered.

In some high-speed PCB board reverse engineering designs or special applications, EMC/EMI etc. also need to be considered.

In some high-speed PCB board reverse engineering designs or special applications, EMC/EMI etc. also need to be considered. The power supply is the basis to ensure the normal operation of the hardware system. Detailed analysis is required in the gerber file design cloning: the power input that the system can provide; the power output that the single board needs to generate; the current size that each power supply needs to provide; the power supply circuit efficiency; the allowable fluctuation of each power supply Scope; the power-on sequence required by the entire power system, etc.